Perfect Bound Binding Services in New York

Perfect binding is a common part of the binding and finishing process. The perfect binding process includes applying adhesive materials to the spine of book, magazine, or catalog pages as a way to keep them bound together in a secure fashion.

It is common for a soft paper or paperboard or paperback cover to be attached to the binding adhesive area. The most traditional publications utilizing perfect binding are: paperback books, catalogs, catalogs and premium magazines.

Perfect Binding process: Gathering Phase

The process of perfect binding is one of the simpler methods of binding, with many state of machinery introduced of the past few years.

Post printing and folding, book signatures are compiled together in the proper sequence through the use of a gathering machine.

These machines comprise of several pockets that hold each individual signature.

In the gathering phase of binding, the separately printed inserts (advertising supplements, give-aways, subscriber reply cards, etc.) or the foldouts need to be assembled and included in the gathering process. When the signatures have been gathered, the book-length pile of the signatures is referred to as a book block.

Perfect Binding: Backbone Cutter Process

In perfect binding, the signature folds at the book’s spine must be removed so that the pages can be aligned squarely at the binding edge. This aids with the adhesive strength.

Post gathering, book blocks are carried with clamps with the spine down over to the binding section. Where the book spine protrudes from underneath the clamps, knives, saws, and/or shredders are used to cut off or remove the signature folds.

Once the folds are cut away, the book spine must be roughened for the adhesive to maximize its staying potential.

Perfect Binding : Adhesive Process

The book block is taken to the gluing location, while still clamped together.

Here an applicator wheel will force the adhesive onto the book spine. It is common for multiple glue pots to be used to apply different adhesives in separate layers.

A paperback book, for example, will have a layer of low-viscosity, hot-melt adhesives applied to it to bind the pages together. Later, one layer of high-viscosity, hot-melt adhesives are used to attach the book block to the book cover. With a thicker publication, like an oversized catalogs, it is standard to use as many as three different adhesives.

The Cover Feeder Process When Using a Perfect Binding Machine

After the application of specific adhesives, the book cover is then applied to the book block. Next, a feeding mechanism will score the book cover where it will be folded to encompass the book block.

Then the cover is pressed onto the book backbone while nippers pinch the book cover around the book spine. At the same time, clamps will press the front, back, and sides of the cover around the book block. The bound book will then be sent for trimming.

The Trimmer Process of the Perfect Bound Book Printing Services

When the adhesives used have cooled, the top portions of the book block’s folded signatures will need to be split and trimming around the sides may be required.

Three-knife trimmers that are located in-line or off-line will be able to trim the three unbound sides at the same time.

In certain situations, the binding is done in what is referred to as “two-up” in which two books happen to be bound together as one unit. Then the two books must be separated prior to being trimmed.

Perfect Binding; The Counter Stacker Process

The last part in the perfect binding process is what is referred to as the counter-stacker which is a device that counts the individual units coming off the finish line.

This unit also stacks the units for shipping. Our perfect binding equipment is capable of binding as many as 18,000 units per hour.

Regardless of the process name, perfect binding is not actually “perfect.”

There are many challenges such as rigid adhesives causing books to not lie flat, and the spines of paperback books being distorted horribly by mistreatment. This said, it is still one of the most effective and highly used processes to date.

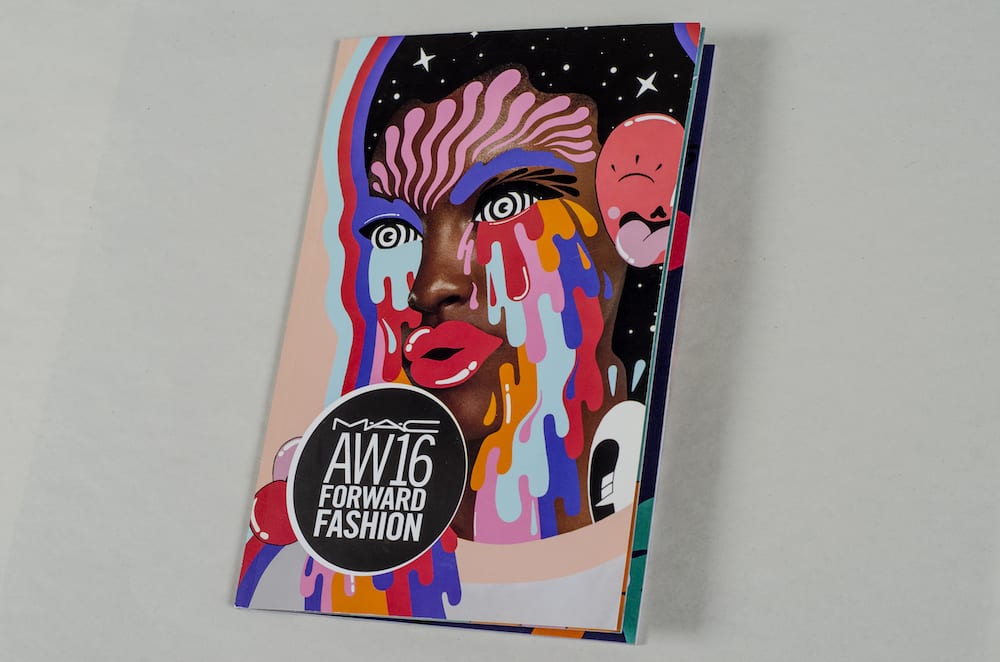

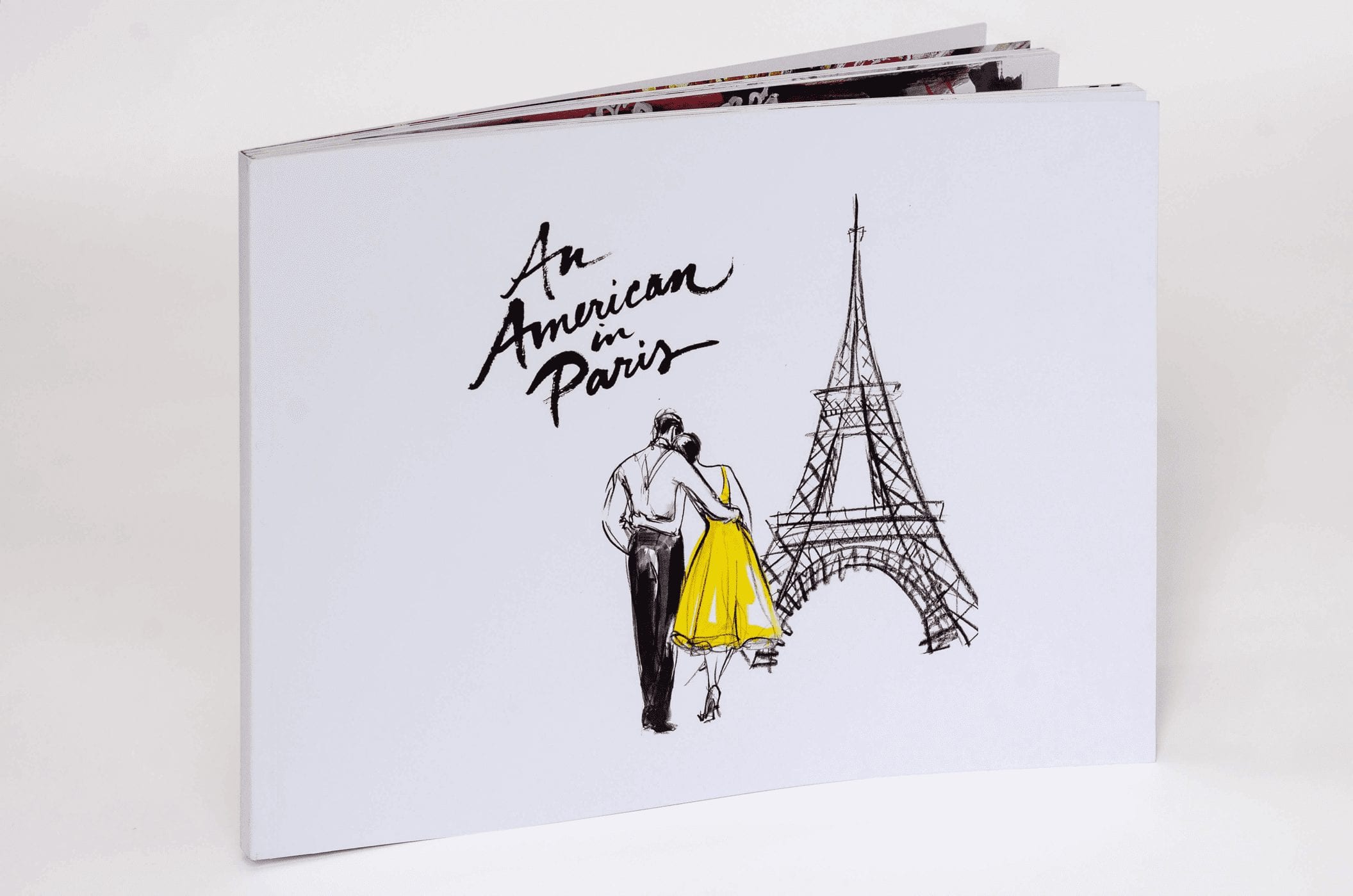

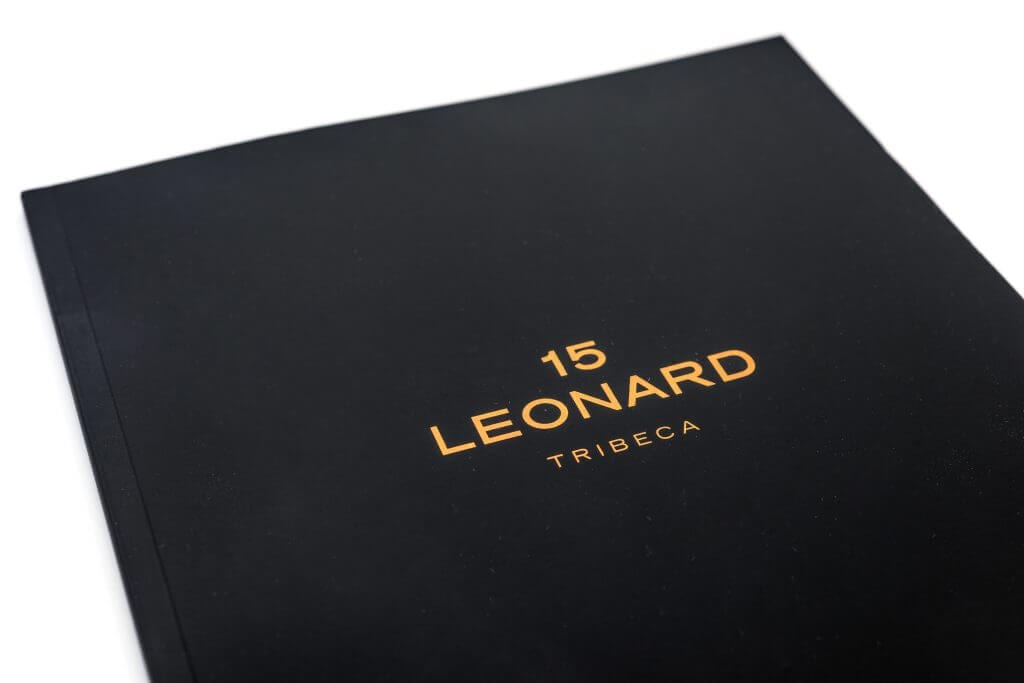

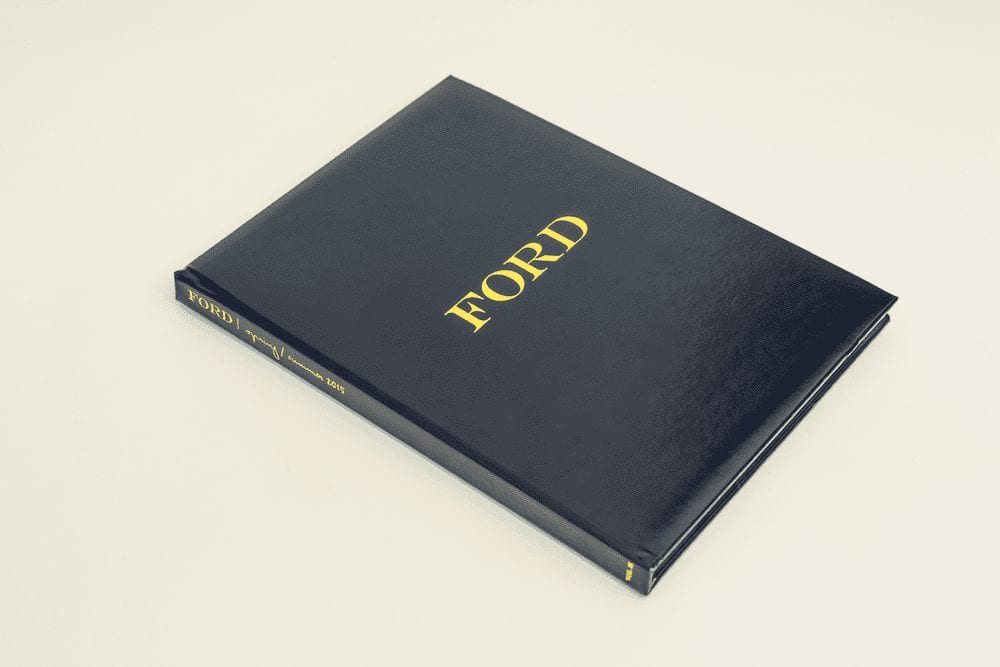

VSL Print offers the Best NYC Book Binding Service

Varick Street Litho is at the cutting edge of binding. Serving both the local New York area and with the ability to serve local, national and global markets. VSL Print specializes in Binding Services, Collating & Gathering, Book Binding, Folding, Case Binding, Imposition Layout, Mechanical Binding, Perfect Binding, Saddle Stitching, and much more.

We have years of experience and have seen all kinds of different complicated situations and challenging products. Our team can successfully guide you to the ideal binding outcome you have in mind.

Contact us today to learn how we can help you with your next project.

Common FAQ

How many pages do you need for perfect binding?

For a printed book, binding options are related to the page count. Perfect binding or adhesive case wraps require a minimum of 24 pages.

What is the difference between perfect binding and saddle stitch?

Both saddle stitching and perfect binding are ways to bind a book or a magazine. Saddle stitching is gathering pages together, then folding them and stapling them along the crease in order to create a book.

What is perfect bound binding?

Perfect Binding is a common soft cover book binding process that is often used within the industry. With

What is perfect bound paperback?

A “Perfect” paperback is a binding term that refers to how the paperback cover is attached to the page block, and also how the pages are attached to each other. A “